Are there objects in your company that need to be managed and tracked? Whether it's managing deposit boxes, measuring equipment, IT equipment or access cards.

If YES, then this article is made just for you.

In this article, I present a suitable solution that is quite easy to use for the operational colleagues using the example of deposit boxes.

For the transport of consumer goods, it is always necessary to provide suitable special boxes. In some cases, the value of the boxes even exceeds the value of the contents, which makes precise management of deposit boxes necessary.

Used tools

- Airtable as database

- make.com as a control and automation solution

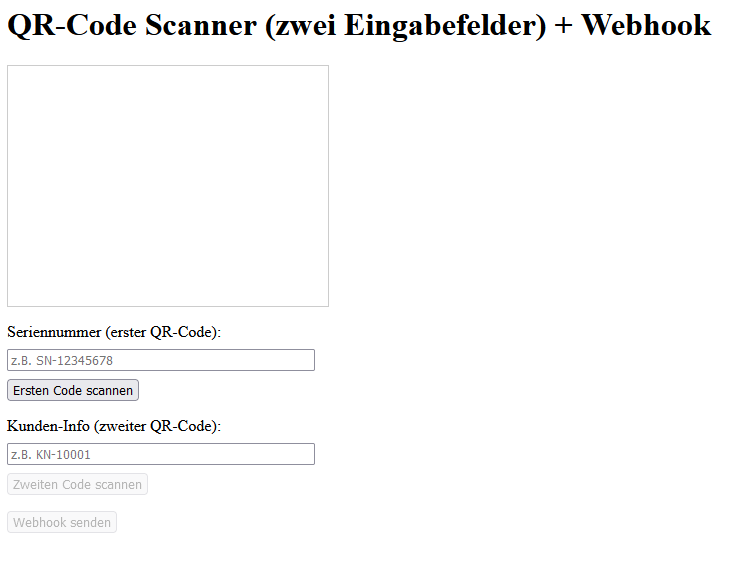

- A simple website with JavaScript for data entry

The running costs for this solution depend a little on the number of parts listed and the number of transactions. However, a fully functional test environment is possible at no additional cost, as both Airtable and make.com offer a free plan.

How does the process for managing deposit boxes work

Preparation

First of all, each deposit box must be given a unique serial number. To avoid typing in the serial number in the following process, the serial numbers are stuck to the boxes as QR code labels. The use of QR codes has the advantage of error correction. Up to 30% of the QR code can be destroyed or dirty to still enable reading (Wikipedia). In addition, compared to non-optical codes, such as NFC tags, a larger distance to the label is permitted and there are no restrictions on the base material.

In order to assign a box to a customer, the customer number must also be available. In this example, the customer number is also printed as a QR code on the customer order. If an ERP system is used, this code can usually be printed by simply adjusting the layout.

Regular workflow

The data is then entered using any smartphone or tablet. On a simple website with JavaScript code, the numbers of the deposit box and the customer are then transferred directly to the automation tool. As soon as a serial number is entered without specifying a customer number, it is marked "back in the warehouse".

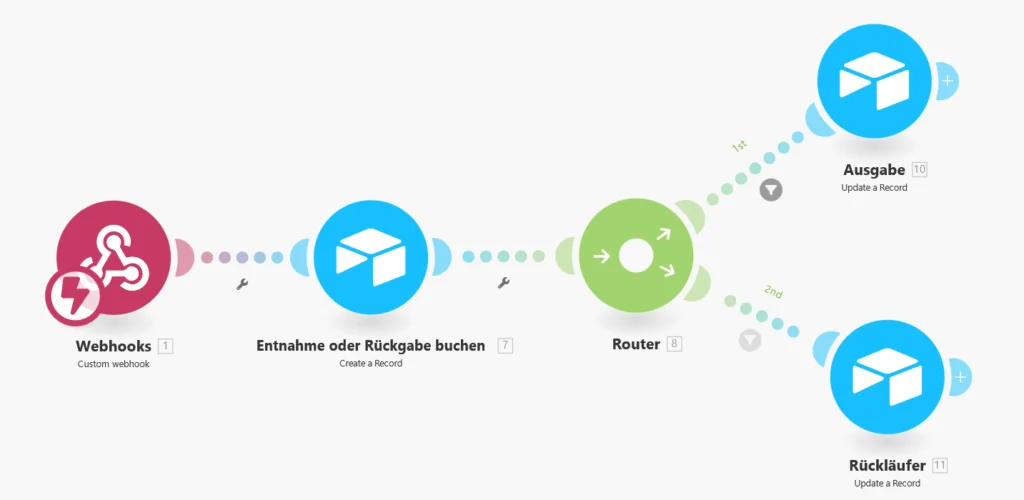

After the two values have been transferred, a new entry is created in the box history. The current status of the box (at the customer / in the warehouse) is then entered in the corresponding table.

Administration of the deposit boxes

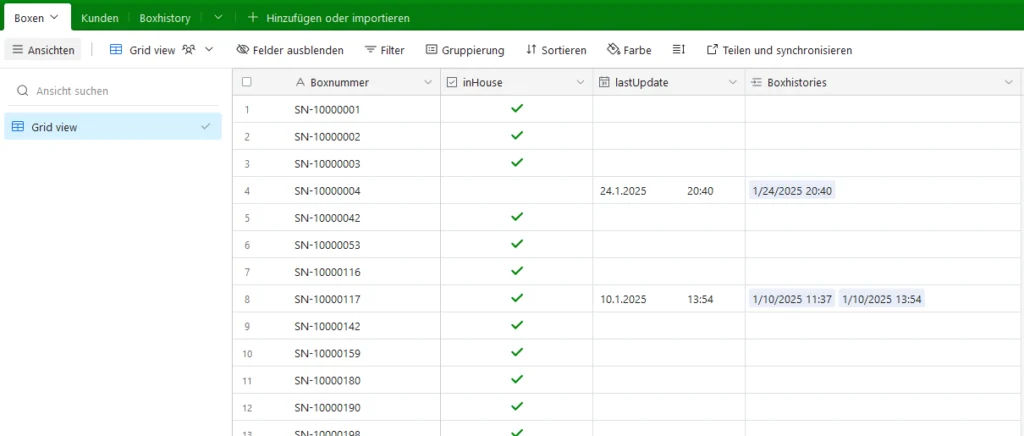

As a result, three tables are available for managing deposit boxes.

- Table Boxes:

Here the serial numbers, the current location, the last booking and a reference to the next table Boxhistories are stored.

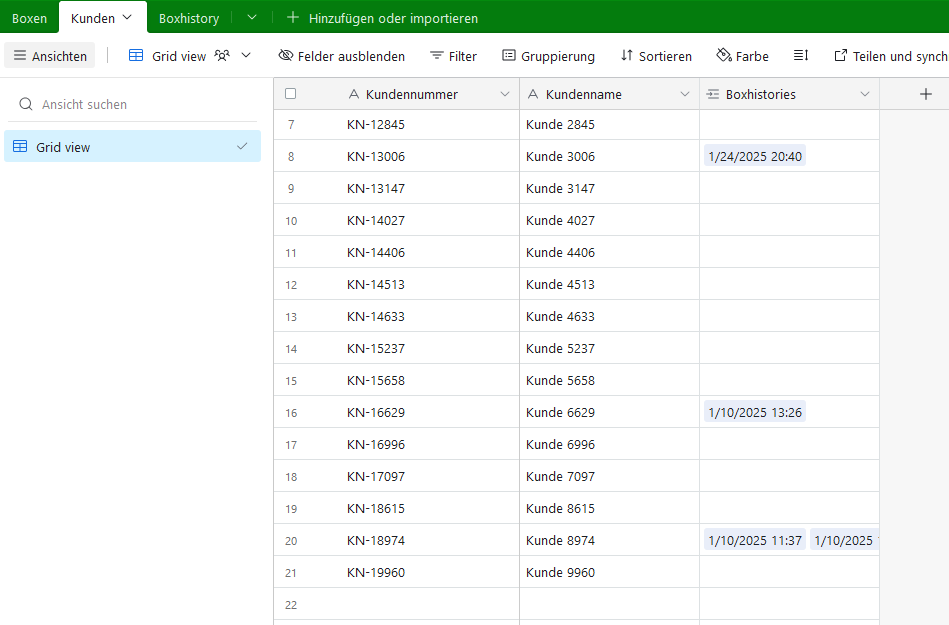

- Table Customers:

For managing customers. In addition to the customer number, the name can also be entered. There is also a column with the associated box histories, which gives you a direct overview of the bookings made with these customers.

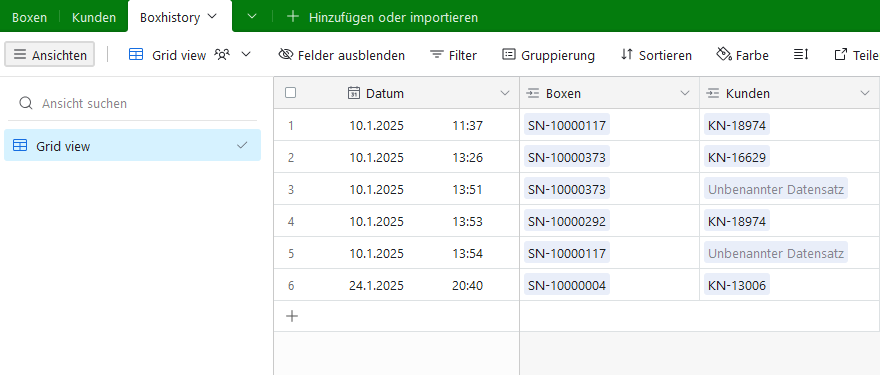

- Table Boxhistory:

Here a timestamp as well as the reference of the box and, if applicable, the customer is entered.

By storing the data centrally, appropriate evaluation can be carried out at any time.

Additional options

The central data makes it easy to set up further automations, for example to send an automatic reminder to the customer after 8 weeks. The columns could also be expanded to manage repairs, purchase dates, inspections, and much more.

This solution is therefore very easy to implement not only for the management of deposit boxes, but also for any type of object management (measuring equipment, IT equipment, access cards, etc.).

If you are interested in trying out the solution yourself or are looking for a different solution for your company, just get in touch with me or arrange a Free initial consultation.